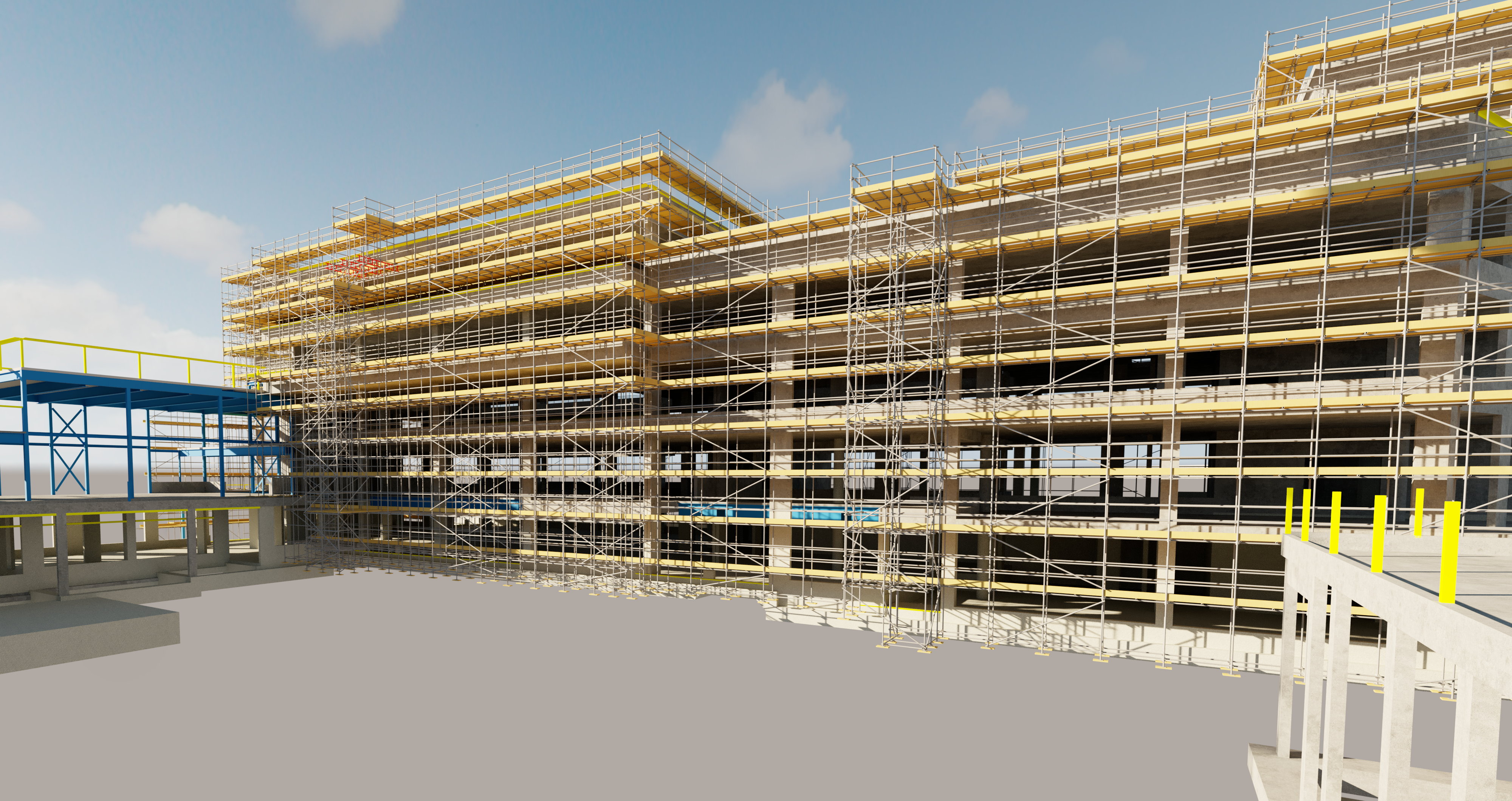

Millcroft is currently supporting the construction of one of Kent’s largest new educational facilities, Alkerden Academy, after securing the scaffolding contract for the £80 million project.

Located in the Whitecliffe Eastern Quarry Development in Ebbsfleet Garden City, the academy will provide more than 2,200 primary and secondary school places, with an eight-form secondary school of up to five stories, and a two-storey primary school. The 11.1-hectare campus will also include a nursery school, community sports hall, sports pitches, parking and access roads. The project, being delivered by GRAHAM Construction for Eastern Quarry Limited (EQL) is due for completion in July 2026.

Millcroft began work on site in January 2025, installing scaffolding for the secondary school and will start the access requirements for the primary school in June. The contract is 42 weeks duration for all scaffolding works.

A key challenge of the scaffolding design has been ensuring that the scaffold standards (vertical supports) could safely carry the required load without double standards on the taller sections or extra bracing to keep it stable. Based on current industry guidance, this would have been necessary, potentially increasing material costs and causing access obstructions.

To solve this, Millcroft’s design team used 3D structural analysis software to model the scaffold, including the properties of the structural transoms (horizontal members) and tie positions. This enabled Millcroft to run a critical buckling analysis to see how much load the scaffold could safely handle under the project’s specific conditions.

The analysis reduced the effective length, ultimately enabling a 12% increase in axial loading, which was enough for most areas. The team then tested a wider base design, which increased the load capacity by 23% from the original.

In taking this approach and fully understanding the structural properties of the prefabricated transoms, we were able to remove the need for double standards and ledger bracing. This meant clear, unobstructed access to the working platforms.

The client and subcontractors gave great feedback on the visual 3D model, as it helped them to fully visualise and plan their access to carry out the work.